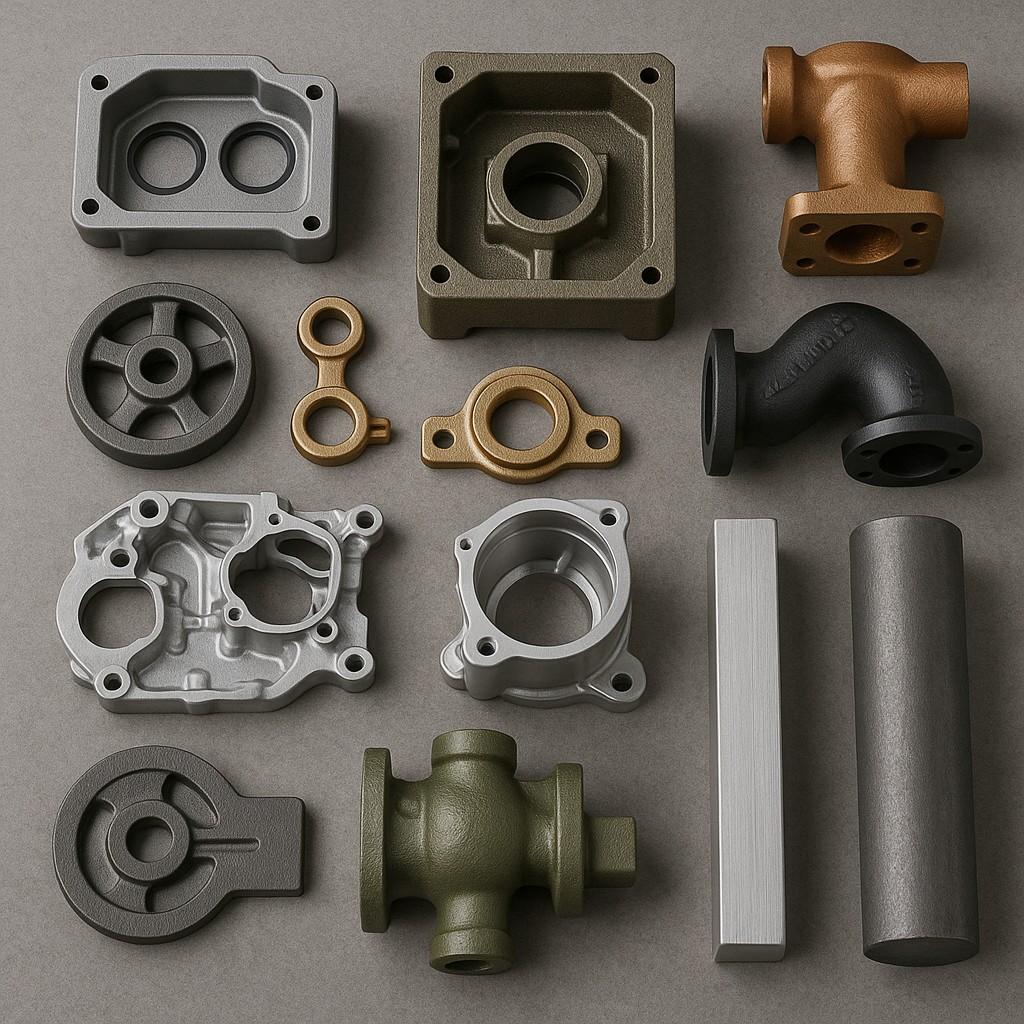

Best Industrial Metal Casting Manufacturers in India

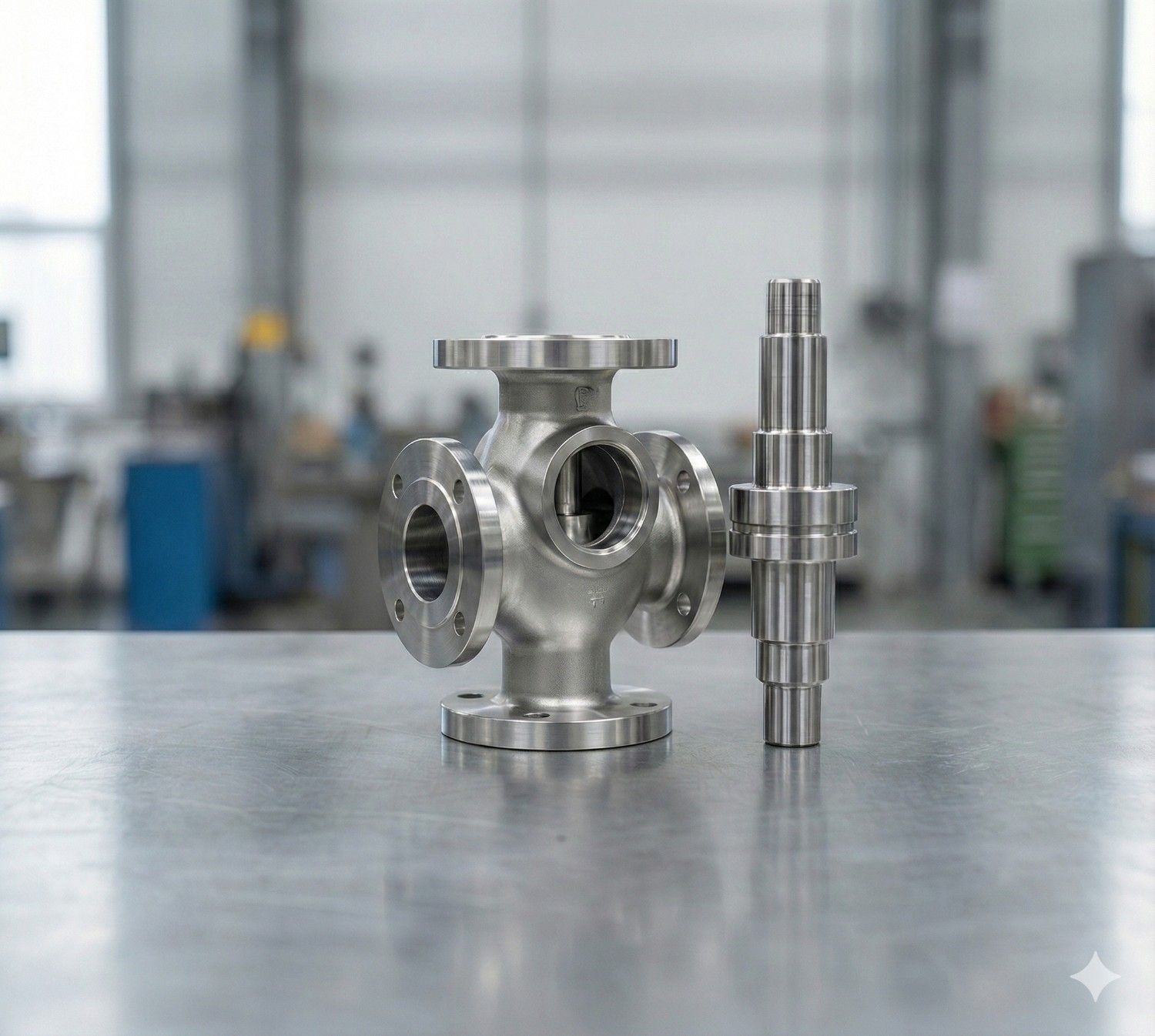

At Sharma Technocast, we deliver precision-engineered metal casting and fully machined components designed for performance, durability, and reliability. As a leading best metal casting manufacturers in Ahmedabad, India. we specialize in investment casting, sand casting, gravity casting, ductile iron casting, centrifugal casting, aluminum casting, and brass casting — serving industries such as automotive, aerospace, heavy machinery, and general engineering.

With a strong foundation in engineering excellence and innovation, our components are manufactured to exact specifications, ensuring superior strength, dimensional accuracy, and consistency for global clients.

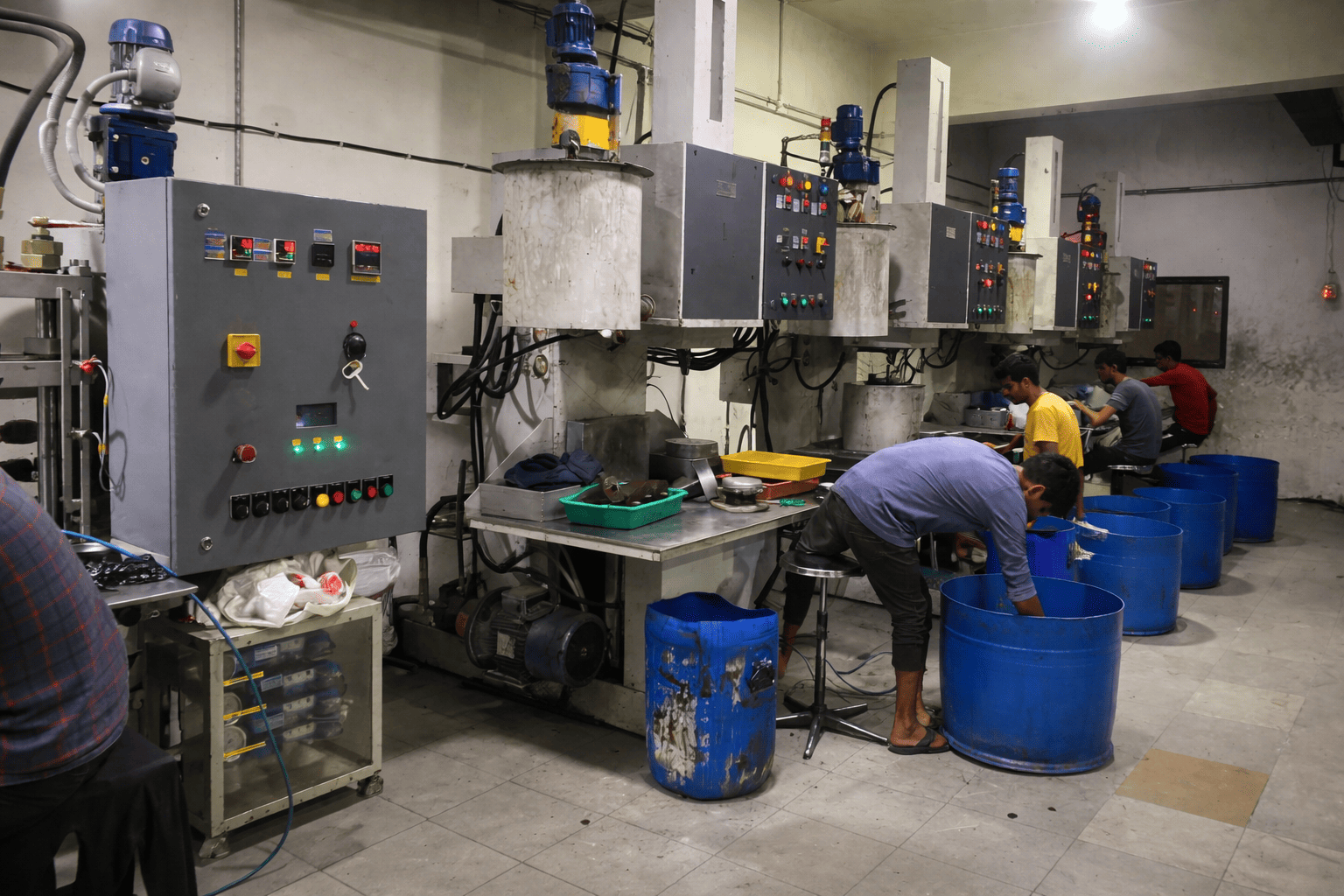

Integrated Metal Casting Manufacturing Facility

We operates a fully Integrated Metal Casting Manufacturing Facility in India equipped to handle casting and machining of graded cast iron, aluminum, brass, bronze, and stainless steel materials.

Metal Casting Manufacturing Process:

- Engineering design and pattern development

- High-quality metal casting and mold making

- In-house precision machining

- Stringent quality control and inspection

- Efficient packaging and dispatch

This integrated workflow ensures faster turnaround, higher quality control, and optimized cost efficiency, making Sharma Technocast one of the most reliable metal casting companies in India.

Complete Metal Casting Solutions From Design to Delivery

From a rough concept sketch to a detailed 3D CAD model, we manage your project from design to delivery. With lead times between 4 to 17 weeks, our engineering team offers:

Design consultation and prototyping

Casting simulation and material selection

Production planning and delivery management

Our commitment is simple — precision, reliability, and performance at every stage

Integrated Casting Lines for Sand Casting, Investment Casting, and Centrifugal Casting

Advanced Infrastructure

Sand Casting

Our sand casting facility is engineered to deliver robust, cost-effective castings for medium to large components with complex geometries. With flexible moulding methods and high pouring capacity, we support heavy engineering, oil & gas, automotive, and infrastructure applications.

From prototype development to bulk production, our sand casting process ensures dimensional accuracy, structural integrity, and consistent quality.

Horizontal Parting Line with Flask

Maximum Part Size

| L | 650 mm / 26 in |

| B | 550 mm / 22 in |

| W | 200 mm / 8 in |

| Min | 1.5 kg / 3 lbs |

| Max | 25 kg / 55 lbs |

Horizontal Parting Line Flaskless

Maximum Part Size

| L | 750 mm / 30 in |

| B | 650 mm / 26 in |

| W | 250 mm / 10 in |

| Min | 10 kg / 22 lbs |

| Max | 60 kg / 132 lbs |

No Bake

Maximum Part Size

| L | 1000 mm / 39 in |

| B | 1100 mm / 43 in |

| W | 350 mm / 14 in |

| Min | 10 kg / 22 lbs |

| Max | 200 kg / 441 lbs |

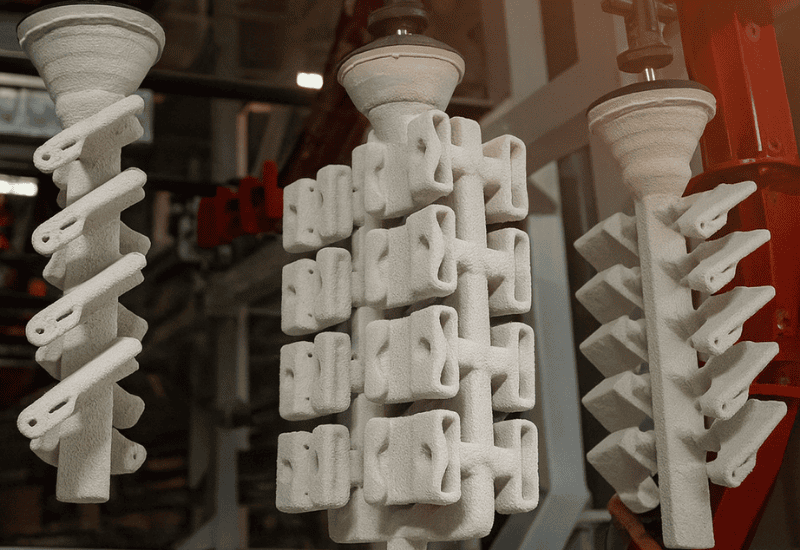

Investment Casting

Our investment casting process is ideal for high-precision, near-net-shape components requiring excellent surface finish and tight tolerances. This method significantly reduces machining requirements and is widely used for aerospace, defense, valve, pump, and precision engineering parts.

We support complex profiles, thin walls, and intricate internal features with repeatable accuracy.

HORIZONTAL

| Typical Part Weight Range | 0.3 kg – 99 kg |

| Part thickness | 3 mm / 0.11 in |

| Accuracy | 0.1 mm |

Stainless Steel: Grades like 304, 316, and 17-4PH offer excellent corrosion resistance and strength for medical, food, and marine parts. Aluminum Alloys: Lightweight, corrosion-resistant, used in aerospace and electronics, often with copper, magnesium, or silicon additions. Carbon & Alloy Steels: Provide structural integrity, used in motors, valves, and firearms. Copper Alloys: Includes brass and bronze for electrical and general industrial uses. Nickel & Cobalt Alloys: High-performance superalloys for extreme temperature and creep resistance (e.g., turbine components). Titanium Alloys: Valued for high strength-to-weight ratio in aerospace.

Centrifugal Casting

Our investment casting process is ideal for high-precision, near-net-shape components requiring excellent surface finish and tight tolerances. This method significantly reduces machining requirements and is widely used for aerospace, defense, valve, pump, and precision engineering parts. We support complex profiles, thin walls, and intricate internal features with repeatable accuracy.

HORIZONTAL

PART SIZE

| OD | 550 mm / 22 in |

| ID | 75 mm / 3 in |

Part Weight

| Min | 50 kg / 110 lbs |

| Max | 800 kg / 1763 lbs |

VERTICAL

VERTICAL

| OD | 60 mm / 2 in |

| ID | 25 mm / 1 in |

Part Weight

| Min | 1 kg / 2 lbs |

| Max | 2 kg / 4 lbs |

Precision Machining

Automatic PLC-based Sand Plant with molding

track line system

CNC, VMC, VTL, and HMC machining centers

ARPA Moulding Machines and No-bake Molding setups

Dust collectors, sand coolers, and 75-ton sand storage

Fully equipped testing laboratory

This world-class infrastructure allows us to maintain precision, repeatability, and reliability across all production batches.

Our Metal Casting Services

Automated PLC-controlled processes for consistent quality

Ferrous and non-ferrous casting capabilities

Rapid RFQ responses and short tooling lead times (as low as 2 weeks)

No minimum order quantity — perfect for both prototypes & production

Full traceability with test certificates for chemical & mechanical properties

Competitive pricing and global shipping capability

Material We Use

- Graded Cast Iron (CI)

- Ductile Iron (SG Iron)

- Aluminum & Brass Casting

- Bronze Casting

- Manganese casting

Each material is chosen for its mechanical strength, corrosion resistance, and heat performance, tailored for sectors like automotive, energy, oil & gas, and heavy engineering.

CARBON STEEL

STAINLESS STEEL

ALUMINUM

ZINC

COPPER

TITANIUM

DUCTILE IRON

17-7 PH

Additional Metal Casting Processes

- Machining

- Surface Treatments & Finishes

- Inspection Testing

- Assembly & Final Integration

precision meets craftsmanship.

Our machining division performs turning, milling, drilling, threading, and surface finishing with exact tolerances. Using modern CNC and VMC systems, every part achieves dimensional precision and flawless functionality — ready for assembly or direct application.

To ensure your parts perform and look their best, we offer:

- Shot blasting, vibratory finishing, and polishing

- Powder coating, anodizing, and painting for corrosion protection

- Custom finishing for industrial or aesthetic applications

Quality is at the core of Sharma Technocast.

Every casting undergoes multi-stage testing using:

- X-ray and Ultrasonic inspection

- Dimensional accuracy checks

- Chemical composition and hardness testing

Our in-house assembly division integrates castings, machined components, and subassemblies into ready-to-use engineered solutions. Whether it’s a small component or a complex industrial product, we ensure precision fit, functionality, and reliability — saving clients time and resources.

Freqently Asked Questions

Metal casting is a manufacturing process where molten metal is poured into a mold to form a specific shape once it solidifies. It is widely used to produce complex, durable engineering components.

Investment casting (lost-wax casting) is a precision casting process that creates highly detailed, accurate components using a wax pattern coated with ceramic material. It is ideal for complex shapes and thin-walled parts.

The metal casting process involves pattern creation, mold preparation, melting metal, pouring, solidification, cooling, casting removal, and final finishing. Each step affects the accuracy, strength, and quality of the final component.

- Sand Casting: Molten metal is poured into sand molds; best for large and complex parts.

- Die Casting: Utilizes high-pressure molds for producing high-volume, precise metal parts.

Aluminium Casting: A casting process specifically for aluminum alloys—lightweight, corrosion-resistant, and used widely in automotive, machinery, and industrial applications.

- Metal casting works by melting metal, filling it into a designed mold cavity, letting it cool, and then removing the solidified part. This produces strong, durable metal components with accurate shapes.

- Sand Casting

- Die Casting

- Investment Casting

- Permanent Mold/Gravity Casting

A cooling curve is a graph showing how molten metal cools and solidifies inside the mold. It helps engineers understand freezing rates, metal flow, shrinkage, and final casting quality.

Steel Casting: Producing components using carbon steel or stainless steel for high strength and wear resistance.

Alloy Casting: Casting metals mixed with alloying elements like nickel, chromium, aluminum, or manganese to enhance performance properties.

Metal casting products include pump parts, valves, automotive components, brackets, housings, gears, machine parts, construction fittings, and various industrial engineering components.

Sharma Technocast provides one of the most trusted metal casting services in Ahmedabad, India offering sand casting, investment casting, aluminium casting, machining, finishing, and custom-engineered casting solutions for industries across India with worldwide delivery.

Why Choose Sharma Technocast For Metal Casting ?

- Proven expertise in metal casting and machining

- Complete engineering support from design to delivery

- Based in Ahmedabad, Gujarat — serving India and global clients

- Commitment to innovation, precision, and customer satisfaction